Brewing Energy saving pilot for an innoVative, Efficient, and enviRonmental beverAGE process

The LIFE program is the EU’s financial instrument supporting environmental, nature conservation and climate action projects throughout the EU. The general objective of LIFE is to contribute to the implementation, updating and development of EU environmental and climate policy and legislation by co-financing projects with European added value. Since 1992, LIFE has co-financed some 4306 projects, contributing approximately € 3.4 billion to the protection of the environment and the climate.

In 2016, AB-InBev has been granted approximately € 800 000 for the LIFE BEVERAGE project that is part of our ambitious dream to create a cleaner world. These LIFE programs contribute to the achievement of the objectives of the Europe 2020 strategy and embed sustainability and social responsibility throughout our entire value chain.

Background

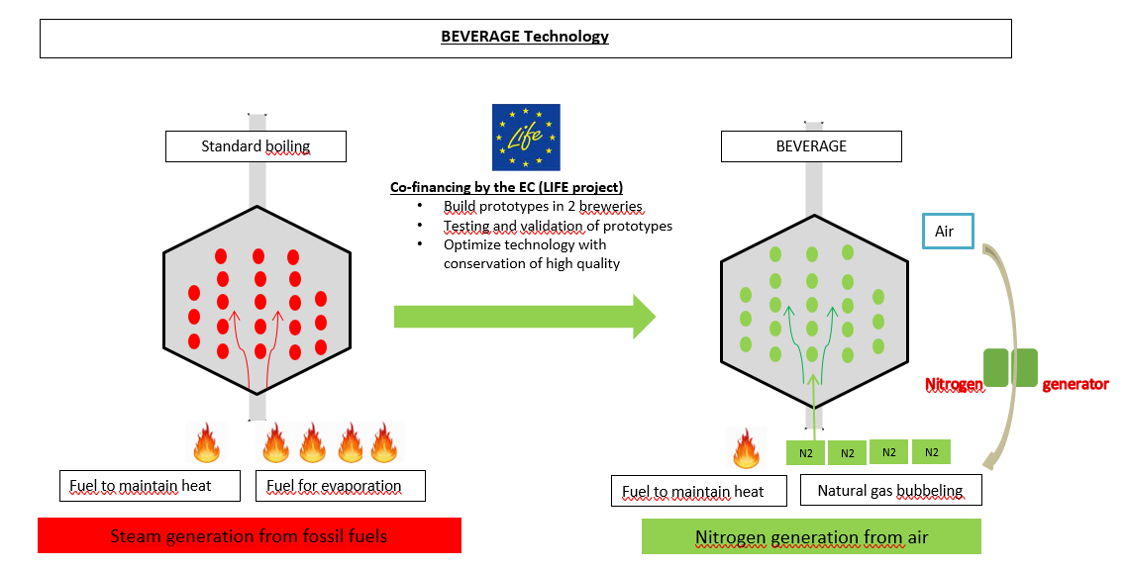

The boiling step is the most energy consuming step in the brewing process, which consumes up to 20 % of the total heat required and generating high levels of greenhouse gases. Previous research at AB-InBev led to the publishing of the patented technology of “Method for treating a wort in a boiling kettle”. Fuel and water consumption can be drastically reduced in this process step by a disruptive innovation; using atmospheric air as the ultimate green resource. Bubbling nitrogen gas into the liquid will simulate the effect of boiling, without the heat requirements.

The boiling step is the most energy consuming step in the brewing process, which consumes up to 20 % of the total heat required and generating high levels of greenhouse gases. Previous research at AB-InBev led to the publishing of the patented technology of “Method for treating a wort in a boiling kettle”. Fuel and water consumption can be drastically reduced in this process step by a disruptive innovation; using atmospheric air as the ultimate green resource. Bubbling nitrogen gas into the liquid will simulate the effect of boiling, without the heat requirements.

Project objectives

As the world’s leading brewer, AB-InBev has an important role to fulfil in addressing serious environmental changes such as water scarcity, resource depletion and climate change. With the LIFE BEVERAGE project we aim to reduce the emission of greenhouse gases caused by beverage production through a new process technology that will be piloted at breweries in Belgium and UK. We are passionate about our brewing traditions, but understand that traditional brewing processes often stand at the gateway to transformational change. The fundamental principles of the most energy consuming step in the brewing process are being questioned and carefully re-verse engineered. In this way AB-InBev aims to:

- lead the way in the transition towards a new standard for a more environmental friendly and sustainable brewing process. Future growth must be maintained, while simultaneously reducing the costs, energy consumption and greenhouse gasses emission.

- develop LIFE BEVERAGE technologies for two different production methods piloting in Jupille and Magor breweries to enable roll-out to all AB-InBev breweries worldwide, which will allow AB-InBev to make a significant contribution to a resource-efficient, low-carbon and climate-resilient economy.

Expected results

With this project we contribute to our 2018 environmental goals and beyond:

- Reduce water usage to a leading-edge 3.2 hectolitres per hectolitre of production

- Reduce energy usage by at least 10% per hectolitre of production on top of the level we achieved in 2012

- Reduce global greenhouse gas emissions in beverage production by another 10% per hectolitre of production.

With a successful realization of the pilots, we estimate the following impacts in the 2 breweries:

- Reduction of water usage with 2% on top of the level achieved in 2014

- Reduction of energy usage with 12%

- Reduction of carbon footprint with 8%

While aiming at reaching these environmental goals, the brand integrity and high quality standards of our beers needs to be maintained or improved.

Related materials

- Beverage Brochure

- Beverage Brochure (FR)

- Beverage Poster

- Laymans Report

- Laymans Report (NL)

- Life Socio Economic Assessment

Related news

- Launch of two LIFE projects

- Visit European Commission 18 May

- LIFE information day: EU Green Week

- Makers’ town – Autoworld, Brussels, June 20

- Meeting minutes of discussion with LIFE OPTIMELT

- LIFE REFRESHMENT and LIFE BEVERAGE at workshop Deloitte

- Sustainable food and beverage conference

- Pilot Launch Jupille

- Bioscience engineering job fair Ghent

- LBK Job fair Leuven

- EBC Congress Submission

- Life BEVERAGE project at TID

- Networking with city councils of different EU countries

- Water and Energy Exchange Global Summit in Porto

- Pilot Demonstration at Jupille

- Showcasing how LIFE projects drive AB InBev’s 2025 sustainability goals

- Green Week 2019