The objective of this LIFE project is to develop a new and innovative method to use BSG as a raw material for food ingredients formulation. By developing alternative uses of BSG, AB InBev strives to build a more sustainable brewing process and increase resource efficiency, fully compliant with the circular economy concept. These goals are totally aligned with AB InBev’s dream to create a better world. LIFE REFRESHMENT aims to contribute to the transition towards a circular economy by:

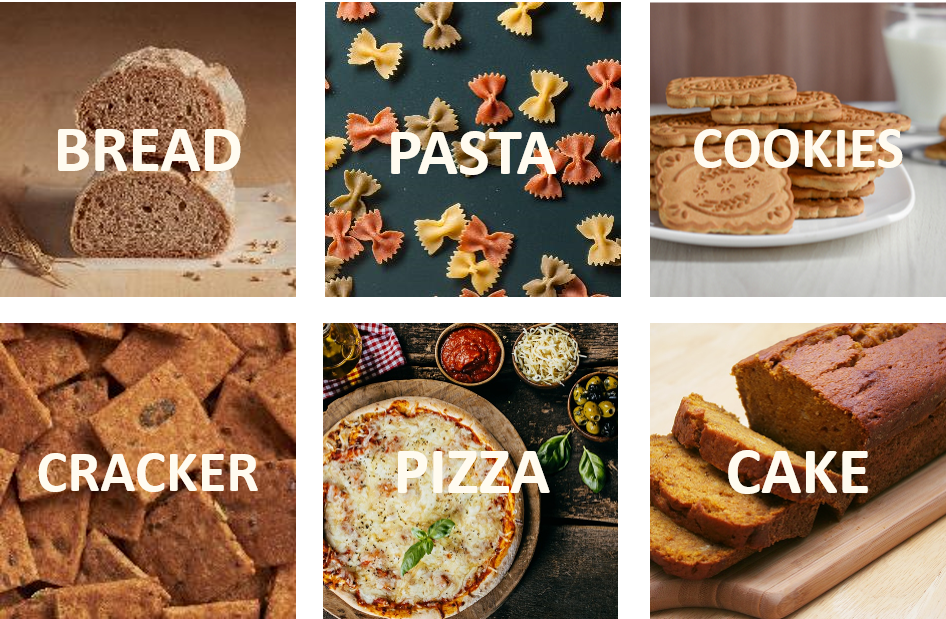

- Developing new ingredients based on BSG, to be used in a large range of food applications, from bakery to beverages, including pasta.

- Developing prototypes of these applications to demonstrate the behaviour of the ingredients.

The ingredients developed through the LIFE REFRESHMENT project include a fermented, homogenized beverage base, a fermented, filtered beverage base and two nutritional powders, rich in proteins and fibres.

The first phase of the process was focused on the development and optimization at lab scale of the beverage bases. These were then transferred to the demo scale in the Research Pilot Brewery in Leuven, t be finally transferred at industrial scale to the Jupille brewery.

In parallel, the development of the powder product line was done, in collaboration with the Jupille brewery. The transformation of BSG into dry ingredients is now implemented and running at semi-industrial scale in Jupille and is commercialized under the name EverVita Pro and EverVita Fibra. (https://evergrainingredients.com/)

The star of the project: Brewer’s Spent Grains (BSG)

The main ingredient in the brewing process is barley:

- Barley is malted prior to the addition to the brewing equipment, releasing the enzymes necessary for the mashing process.

- During the mashing process, the sugars are extracted from the malt kernels, together with soluble proteins and polyphenols and fermented into beer.

- Barley gives to the beer its body and color and contributes to the beer taste.

- The leftover Barley (or spent grain) is historically discarded as a by-product of the brewing process although it is rich in protein and fibers.

Key Achievements

1. Beverage base development

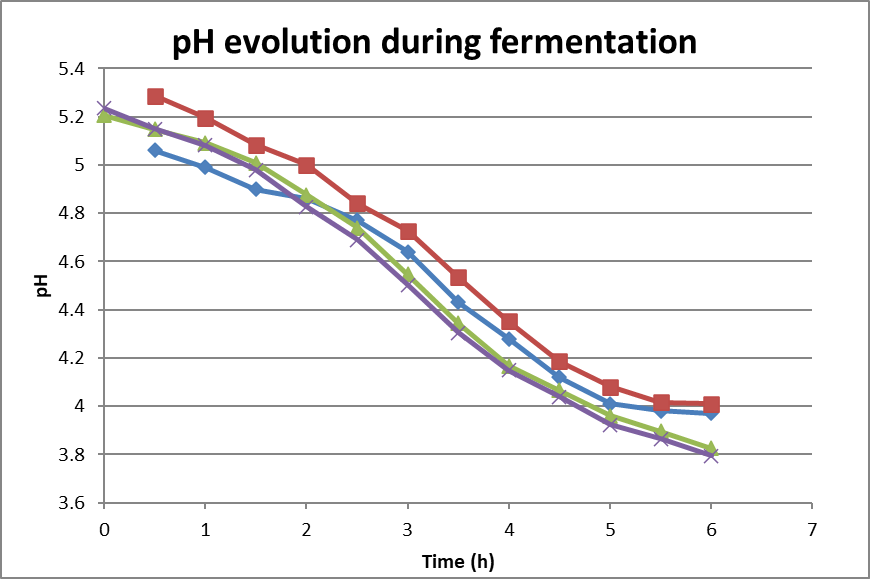

The Yeast and Fermentation lab in Gitec, in collaboration with the University College of Cork, developed a way to ferment and stabilize the BSG, through a proprietary technology and with the help of lactobacillus bacterial strains.

In August 2018, the transfer of the technology to the Research Pilot Brewery of AB InBev in Leuven allowed the team to perform lactic acid fermentations inside the brewery! The technology was transferred at industrial scale to Jupille in September 2019.

The team supported the replication of the technology in the Newark brewery and the launch of Canvas on the West Coast of the US. Canvas was the first beverage using BSG commercialized, and since then reformulated into Take Two, a new barleymilk.

2. Dry ingredients optimization

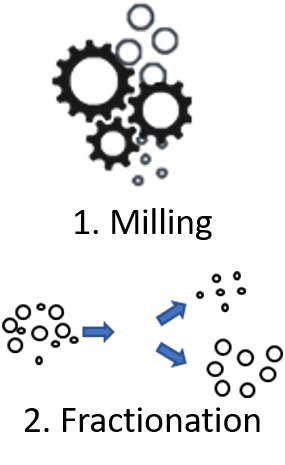

A second range of ingredients was developed. In this process, the water activity of the grains is reduced through drying to stabilize the BSG, instead of a decrease of pH through fermentation. Several drying techniques were investigated, including ring dryers and fluidized bed dryers.

The dry powder is then milled and classified with a patent pending process These two mechanical steps allow to reduce the particle size of the BSG, as well as partially separate the protein and the fibre fractions Combined with the low carbohydrate content, the two fractions have exceptional nutritional properties.

The resulting fractions, commercialized under the name EverVita Pro and EverVita Fibra, have been tested in various applications. The first commercial agreements for the supply of those ingredients have been signed at the end of 2019.

3. Dissemination and project management

The project team attended and organized more than 12 events during the 3.5 years of the project. The results of the team have been shown on the project website and shared through the team members’ social media.

Related materials

Related news

- LIFE information day: EU Green Week

- Makers’ town – Autoworld, Brussels, June 20

- Visit European Commission 18 May

- LIFE REFRESHMENT at EFFoST

- LIFE REFRESHMENT at Innov’8 conference

- Networking meeting with LIFE Optimelt